Efficient Mist Generation: Utilizes a clog-free vortex mist head for consistent oil mist production. Low Maintenance: Minimal upkeep required due to robust design and durable stainless steel construction. Safety Certified: Approved for Class 1 Group B/C/D Div 2 or Option Div 1 hazardous locations. Optimal Control: Monitors and regulates all mist generation variables for reliable performance. Electrical Efficiency: Uses power only for controls, not for the production of oil mist.

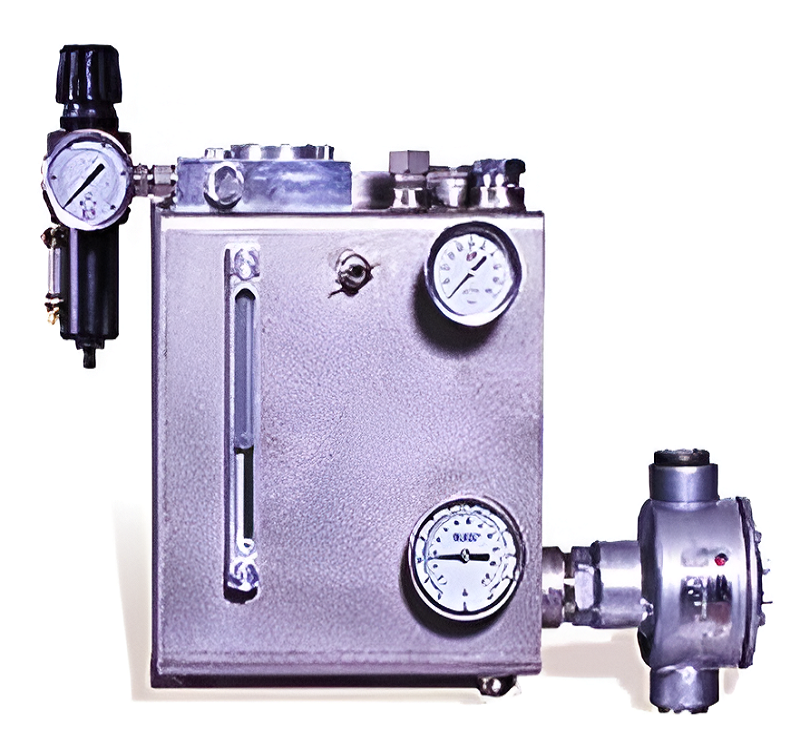

- Main and standby mist generators with individual reservoirs of 33 liters

- Oil mist density sensor

- Automatic/remote operated air pressure regulator

- 300 liter bulk tank, Internal bulk tank receives oil mist in- order to prevent oil oxidation

- Monitors and controls all mist generating variables

Air temp control insures precise control of mist density

• SS 304

• Optional 316/316L

- Fully enclosed pedestal mounted

- 36 - Litres SS reservoir with pressure- relief valve, oil level sight gauge and clean-out panel

- Thermostatically controlled immersion oil heater and reservoir-mounted oil temperature gauges

- High/low mist pressure transducer and mist pressure gauge

• SS 304

• Optional 316/316L

- Three gallon reservoir with pressure valve, oil level sight gauge and low level

switch.

- Thermostatically controlled immersion oil heater and reservoir mounted oil temperature gauge.

- Low oil level switch

- Air pressure regulator with gauge and auto drain air filter

• SS 304

• Optional 316/316L

- Divides mist flow from header drop

- Distributes mist to six lube application points

- Allows visual inspection of oil mist and draining of oil

- Equipped with integral drain valve and tubing connection to divert oil to collection container

• High temperature, sight glass tube

• SS 304 MOC of body and valve

• SS 316, tube fittings

- For use with application of purge mist/wet sump

- Provides venting of mist to the bearing housing

- Provides clog-resistant mist flow into and from the cavity receiving purge mist

• Aluminum body

• SS 316 tube fittings Options

• SS 304 MOC

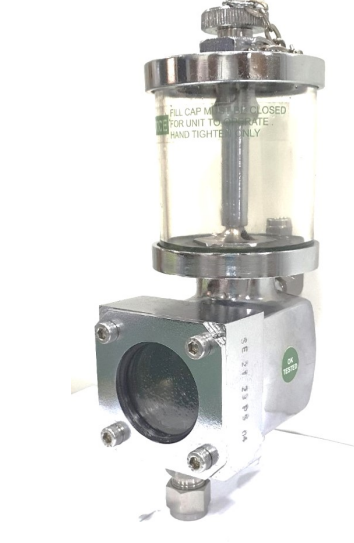

- Maintains oil level inside bearing housing

5oz. capacity oil reservoir with fill cap

- Equipped with viewing chamber to set and check oil level in bearing housing

- Ensures no pressure build-up in bearing housing

- Compatible with Oil Mist Lubrication purge mist vent/fill assembly and connection to oil collection

containers

• Aluminum body

• High temperature sight glass tube

• SS 316 tube fittings

- Collects coalesced oil from bearing housing

- Keeps equipment base plates clean

Eliminates oil drain to sewers

- Easily mounted to equipment foundation

-Sized to require once per month servicing

• SS 304

• Hand Pump is part of closed loop oil mist

System

- This assembly is intended for use with the

Purge Mist Vent/Fill Assembly

- Oil level in the equipment receiving purge oil mist is protected against overfilling

from liquid oil addition by coalesced oil mist

- Mounted to the bearing housing and the unique design allows for accommodation of level control over

a

broad range.

• SS 304

• SS 316/316L

- Maintains oil level inside bearing housing

- 5oz. capacity oil reservoir with fill cap

- Equipped with viewing chamber to set and check oil level in bearing housing

- Ensures no pressure build-up in bearing housing

• Aluminum body

• High temperature sight glass tube

• SS 316 tube fittings

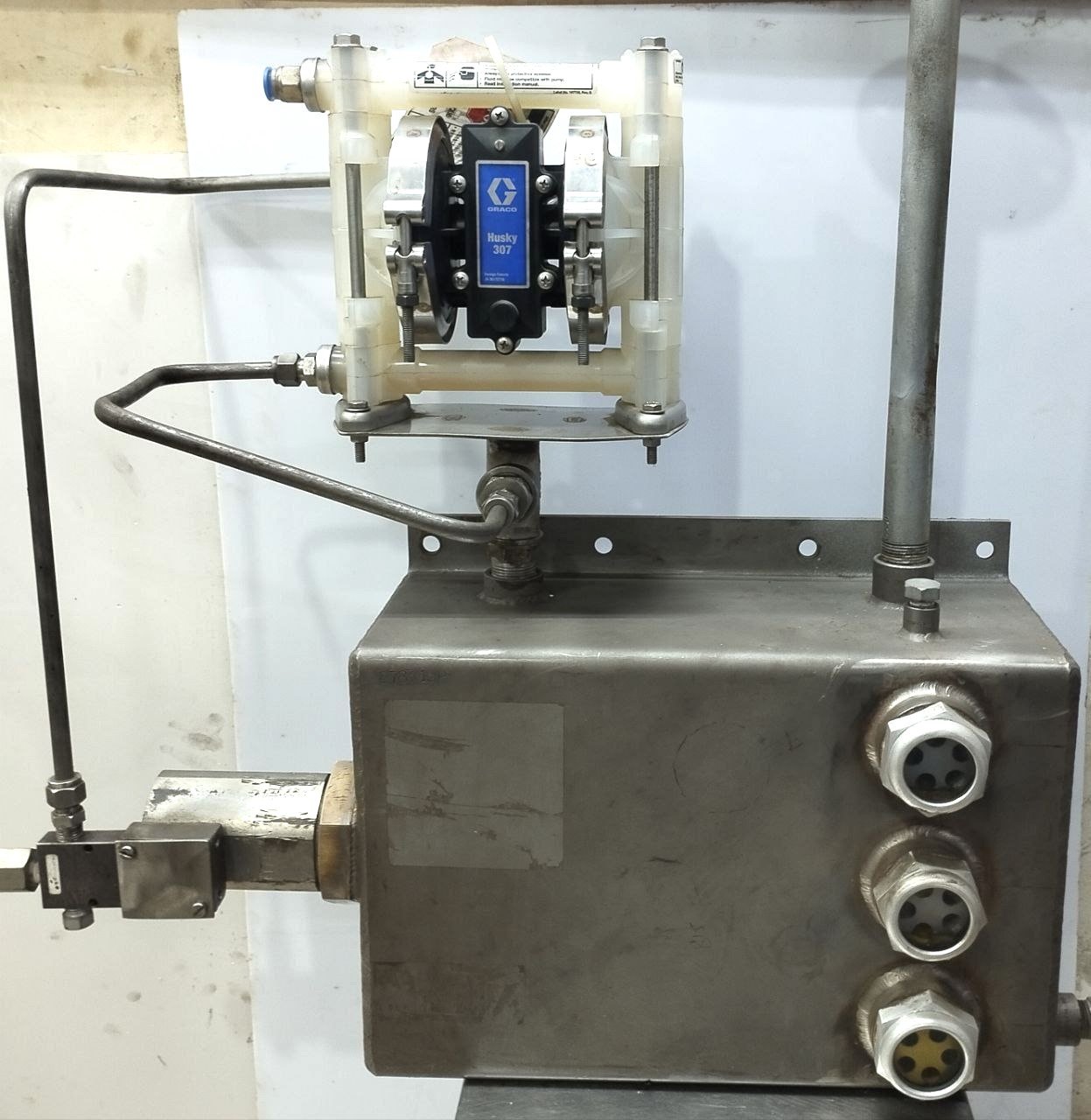

-Collects coalesced oil and automatically pumps/pushes oil to return header (can

be used for closed-loop

or one way system)

- Operated by compressed air (electrical supply not required)

- Provides for reuse of coalesced header oil, reducing oil consumption

- Fully automated

• T 304 SS reservoir

- We offer a full line of quality replacement parts and components for T.F.

Hudgins systems and other

makes of oil mist systems.

- Backed by our technical support and installation services, these accessories

deliver outstanding reliability and value in your applications.

- Drain leg manifolds monitor and maintain header pressure while draining coalesced oil into a

collection

container.

- Monitors oil mist density continuously in the supply header.

- Detects changes in oil/air ratio using light penetration.

- Adjustable sensitivity settings

- Alarms for high/low mist levels

- Can be installed in a Hazardous environment, since it comes with a PESO Approved Enclosure

• SS 304 and Aluminium

* This product can be customized based on your requirements.

The BlazeFlow oil purifier systems manufactured by FEPL are an advanced, effective and reliable solution for removing particulates, water and gases from a wide range of fluids including lubricants, hydraulic oils and transformer oils.

- This assembly is intended for use with the Transmission equipments

- Breather allows the transmission to breathe air when vacuum is inside which expands or contracts

due

to

heating and cooling of lubricating oil during equipment running.

- Breather allows the hot air to escape and cool air to enter into the transmission to prevent

overheating

issue.

• Aluminium

• 3/4" or 3/8" or 1/2"

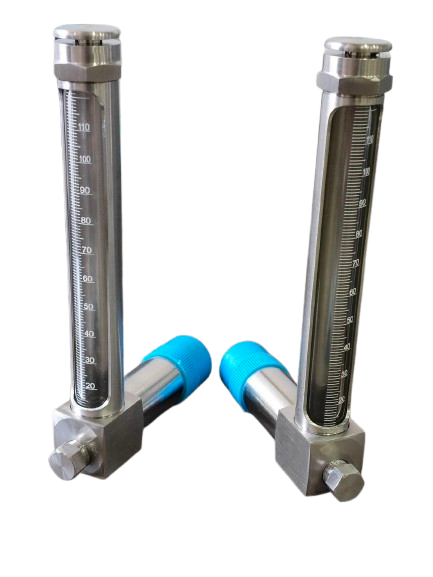

- This type of level gauges have a threaded connection, and are placed laterally

on the wall of the

tank

that contains the oil. Due to its direct contact with the fluid, it provides a quick indication of

the

level in the tubular sight glass.

- The height of the level can be adjusted according to the needs of the process, as well as the

specifications of connections and materials.

• Brass Optional Admiralty Brass

• High temperature glass sight tube with marking

- This type of level gauges have a threaded connection, and

are placed laterally

on the wall of the

tank

that contains the oil. Due to its direct contact with the fluid, it provides

a quick indication of

the

level in the tubular sight glass.

- The height of the level can be adjusted according to the needs of the

process, as well as the

specifications of connections and materials.

• SS316L OR Aluminium

• High temperature glass sight tube with marking

- An automatic pressure relieving device actuated by the static pressure

upstream of the valve, which

opens in proportion to the increase over the opening pressure.

- The pressure at the valve inlet where the relieved fluid is first detected before normal

relieving

action takes place

- The valve inlet pop point pressure at which there is a measurable lift or discharge becomes

continuous

as determined by seeing, hearing or feeling.

• SS316 / SS304

.png)

- The pressure at the valve inlet where the relieved fluid is first detected

before normal relieving

action takes place

- The valve inlet pop point pressure at which there is a measurable lift or discharge becomes

continuous

as determined by seeing, hearing or feeling.

• SS316 / SS304

- For use with FMC Series Auto Drain Leg

- Drains collected, coalesced oil into auto drain leg while maintaining header pressure

- Equipped with integral drain valve Material

- SS 304 body

- High temperature glass sight tube

• T 316/316L SS body with SS pressure gauge

At FEPL Engineering, we excel in delivering precision welding

solutions tailored to

your specific requirements, leveraging expertise in ARC Welding, Argon Welding, and other advanced

techniques to guarantee exceptional durability, accuracy, and craftsmanship in every custom product.

Our skilled team harnesses the latest technology to ensure seamless execution of specialized

fabrications and complex assemblies, bringing your vision to life with precision, excellence, and

unparalleled attention to detail. Our commitment goes beyond just providing welding services; we work

closely with you from concept to

completion, offering customized solutions that align with your goals. We are dedicated to creating

products that are built to last, all while meeting critical timelines and budget requirements.

CCTV camera systems are an important facilities management tool in today's modern industrial plant. A properly planned system can provide you a clear picture of your entire facility. All CCTV cameras offered FEPL are designed to work in the harsh conditions of a refinery or petrochemical plant. CCTV cameras are housed in explosion proof, all-weather, corrosion resistant SUS 316 stainless steel meeting IECEx ExD/IIC/T6/IP67 standards. A CCTV system is only as good as its installation. FEPL will make sure the installation is done right and on-time.

Integrating solar power systems into your facility has become a matter of common sense in today's world. Whether it is to offset your current power consumption, build in system redundancies, comply with government regulations or if you simply want to "go green," FEPL has the right modular solar system for you. FEPL offers a full range of systems to meet every need. The panels we use are IEC/VDE/UL certified. They are also approved by the Ministry of New and Renewable Energy (MNRE) and ICRA Limited. . We can do a full evaluation to see what system is best for you. We can then design and install that system making sure it meets the rigorous standards of your industrial facility.

Pipeline – 1.5” Body (Model: PE 105) is constructed entirely of SS304 with an SS316 flow tube and SS316L electrodes, making it ideal for conductive liquid applications. It operates under a maximum pressure of 100 Bar with a #600 class flange and PTFE lining for enhanced durability. The device features a digital display powered by a 24V supply and offers output options including 4-20mA, Pulse, and RS485. Its aluminum die-cast enclosure is IP67 certified, ensuring protection against harsh environments. Designed to withstand process temperatures up to 85°C, this model is TÜV-SÜD certified and supports a flow range of 16-904 LPM.